Situation

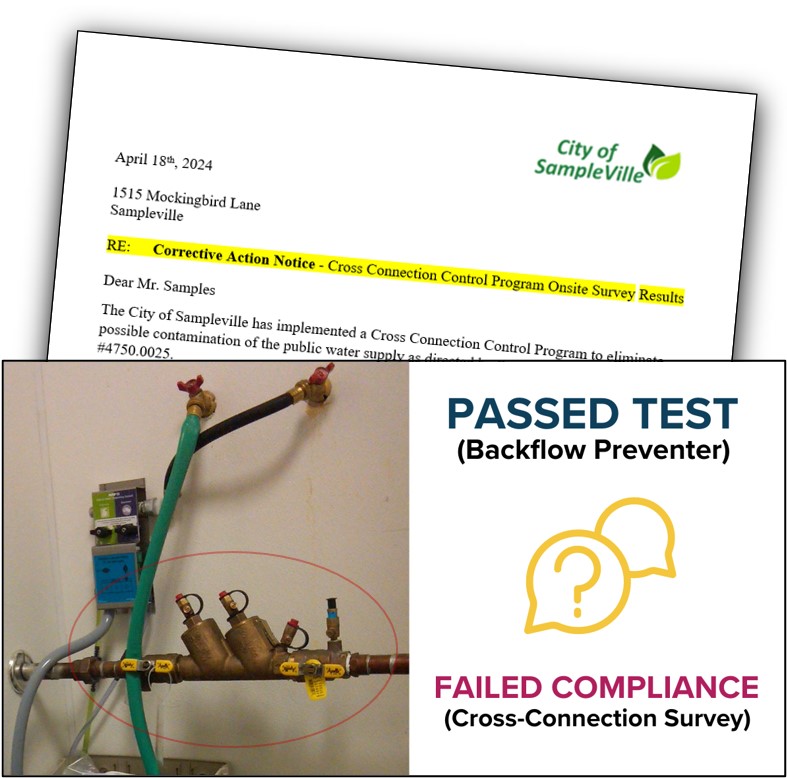

A food processor was having a “bug” problem at one of their major (300,000 sq. ft.) facilities. During routine sampling of their water distribution system, abnormal bacterial growth was detected in several critical zones. In a cascade effect, these findings forced the company to shut down key sectors of the operation, resulting in lost revenue. Additionally, expensive modifications to remaining production systems were needed, in an effort to meet customer demand, and costly bacterial sampling was increased to monitor and record levels. Compounding these issues was the acute scrutiny the company faced by local and state regulatory agencies.

These small bugs were causing big headaches – impacting product quality, employee safety, revenue, and corporate reputation. The parent corporation referred the company to HydroCorp, who had a team on site in less than 24 hours.

Discovery

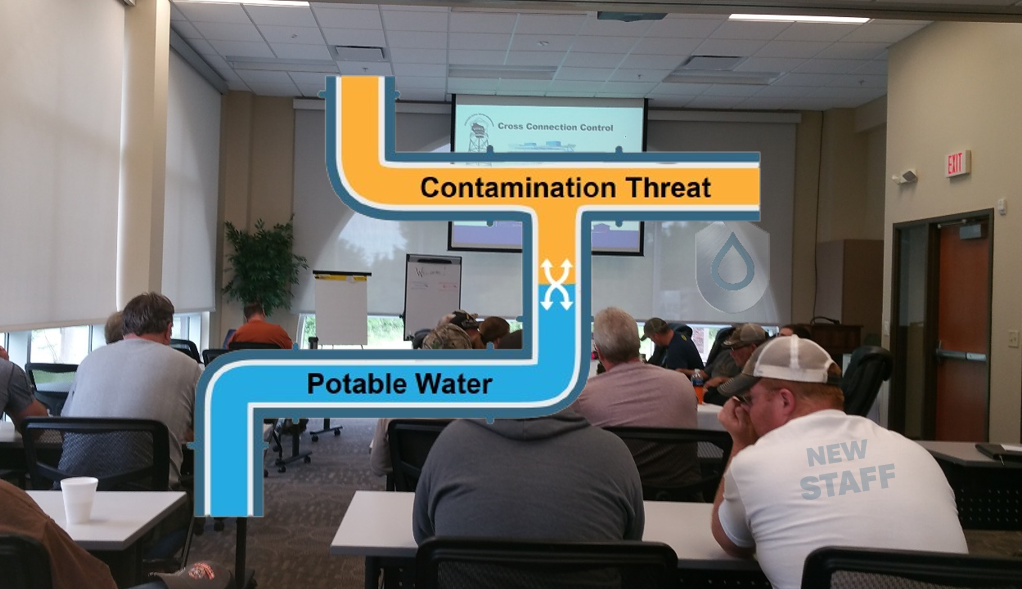

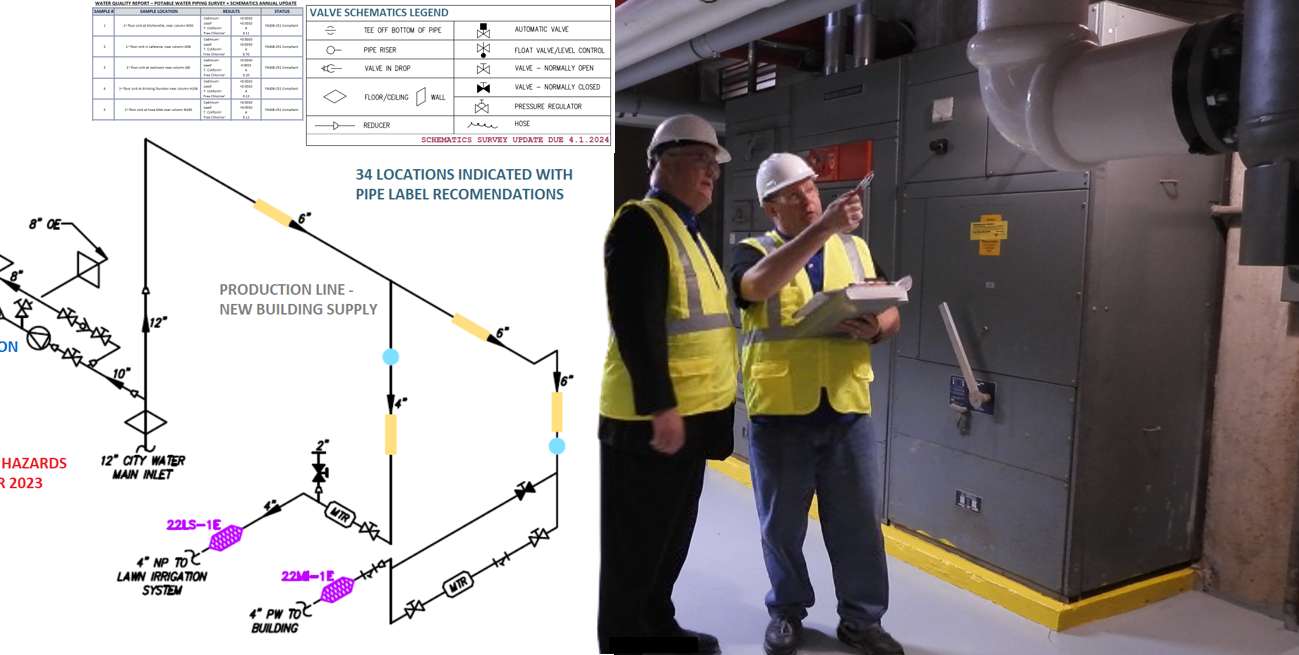

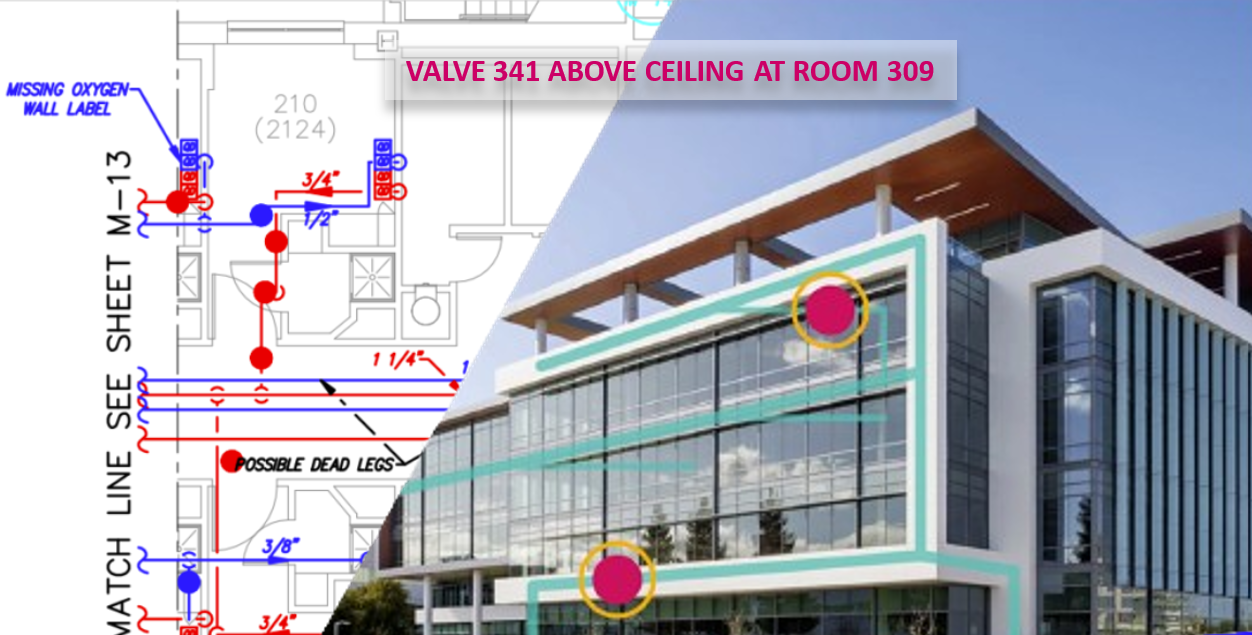

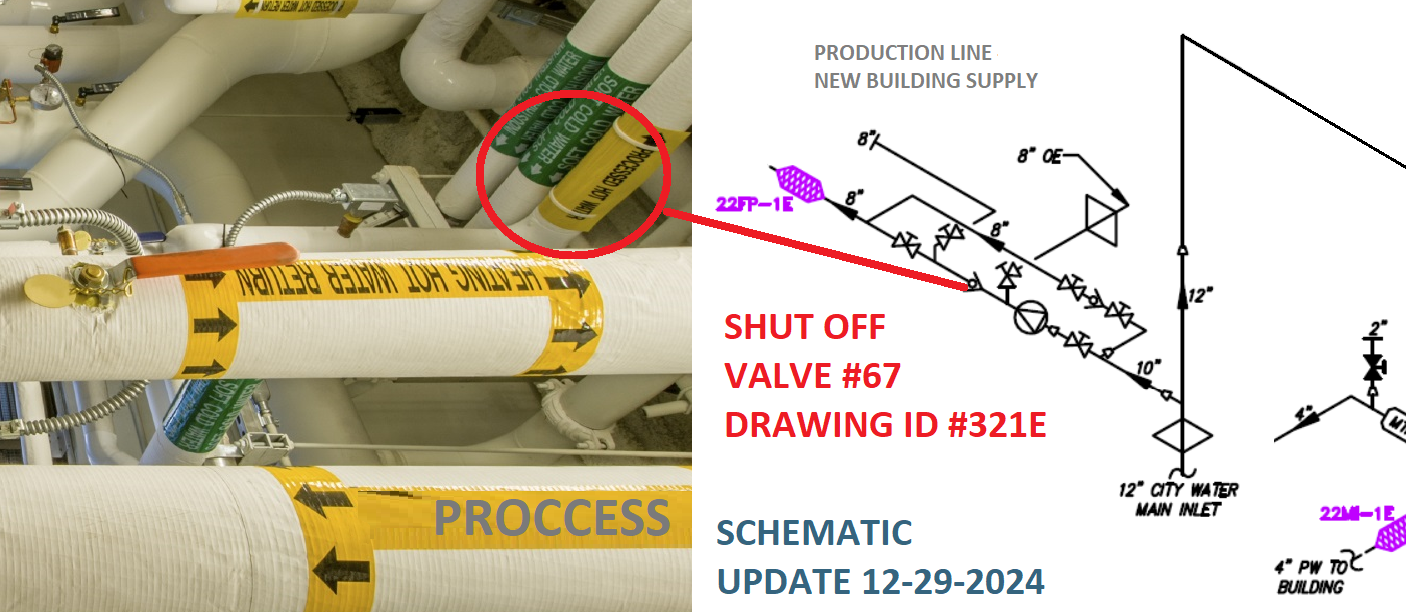

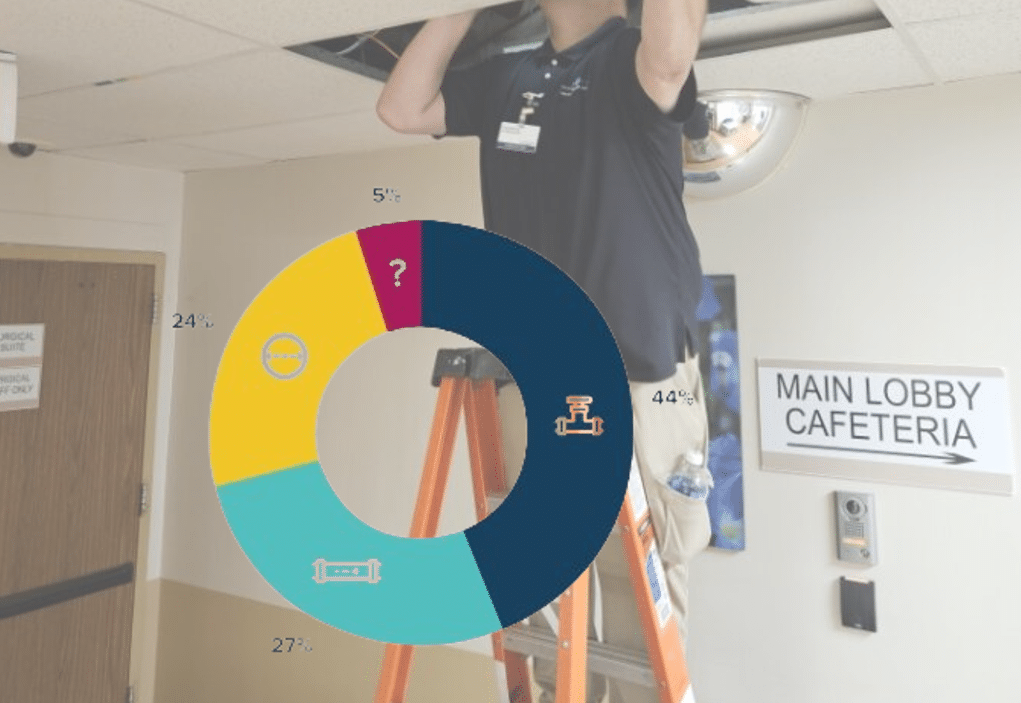

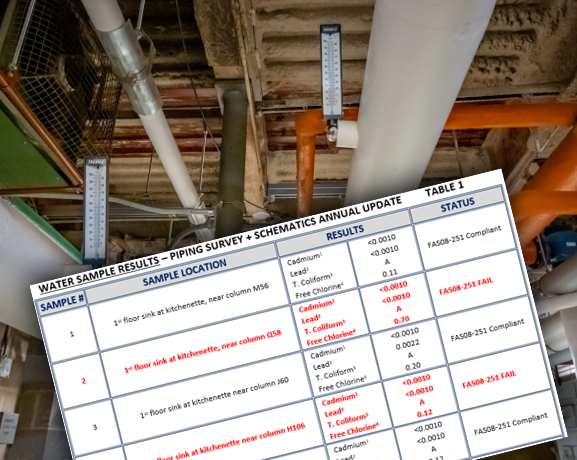

A thorough survey of the plant’s water systems was conducted, and comprehensive piping diagrams were created to help identify areas that might be vulnerable to water quality degradation. HydroCorp then performed in-depth water quality analyses in those areas which, not surprisingly, revealed a series of cross connections between the potable and process water systems.

Solution

HydroCorp recommended strategically re-plumbing affected portions of the system, with the objectives to improve fluid flow, reduce stagnation, and eliminate cross connections. The food processor quickly implemented these measures, and follow-on analyses confirmed water quality for product processing had significantly improved, as did domestic use water for employees and visitors. The engagement, from first fieldwork to final report, was completed in less than thirty days.

Conclusion

“Conscientious food processors and packagers take bacterial contamination very seriously,” says Glenn Adamus, HydroCorp’s Vice President of Operations, “and for very good reason: it can occur anywhere, with virtually any kind of food product. We all know how salmonella turns up repeatedly in the news, from improperly prepared meat, poultry and dairy products. But not long ago, four people died of listeriosis traced to a food processor in Texas…from chopped celery.”

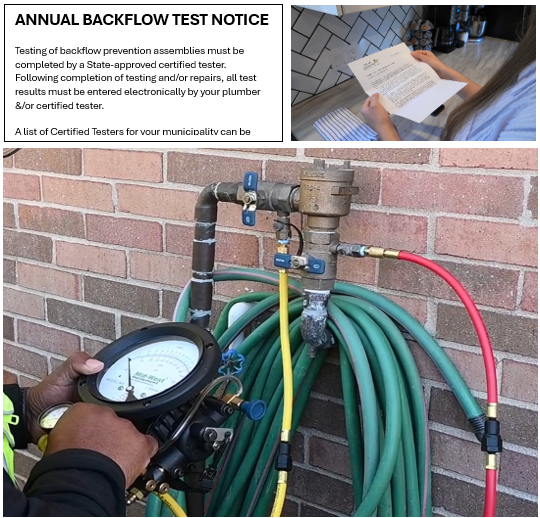

Clearly, a robust cross-connection control program – with up-to-date piping diagrams, regular water quality analysis, and a documented maintenance regime – can give companies a confident foundation for a safe water distribution system.